In May we welcomed Luke Parnell as our new Technical Superintendent, playing a pivotal role in overseeing and managing the maintenance of our vessels.

Chief Executive Stuart Reid said:

“Luke’s familiarity with our current vessels and operations, as well as experience with new builds, will be a real asset for the future.”

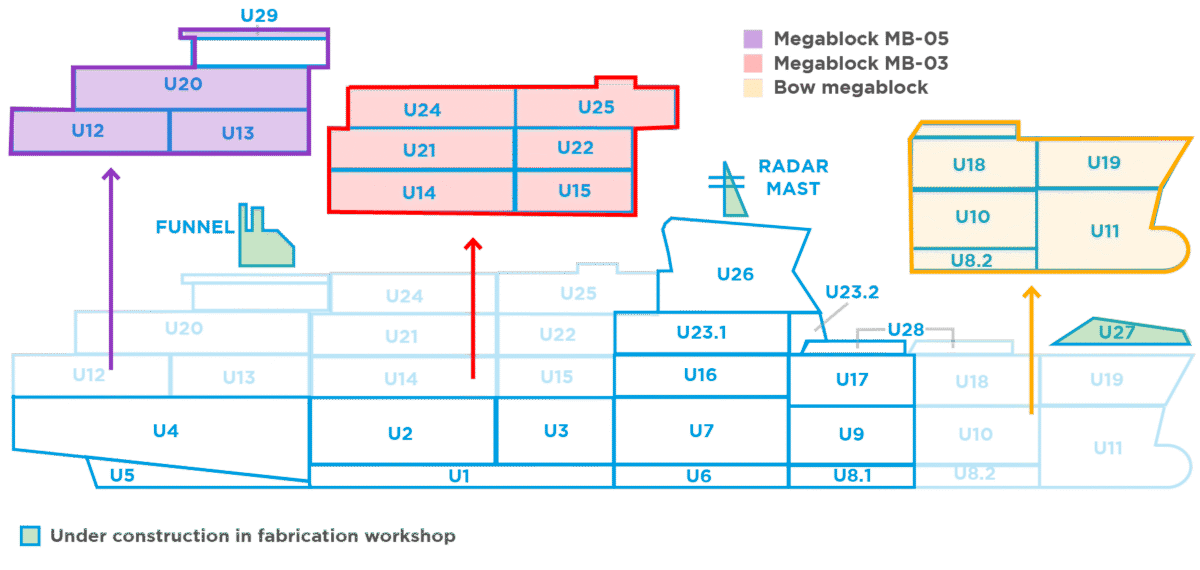

Earlier this month, Luke visited Piriou’s shipyard in Vietnam to familiarise himself with Scillonian IV and Menawethan. He will return at the end of August for a two-week period, providing cover for Chris and Peter during their annual leave.

During this visit, Luke will oversee key stages of progress. On Scillonian IV, he expects to see the completion of welding installation and integrity testing of the starboard fin stabiliser, as well as the final inspection of Void 1 before it is sealed for the next five years. He will also check on the installation of the floating floor on Deck 2, which is on course to be completed during his time in the yard. The main gearbox preliminary alignment should also be finalised, with full alignment scheduled once the vessel is afloat.

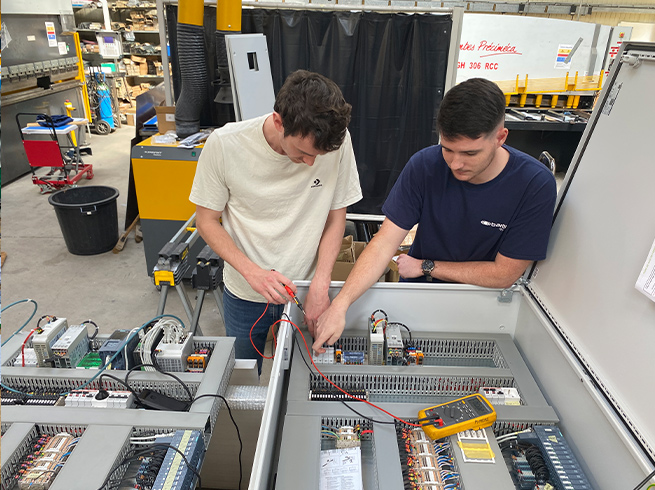

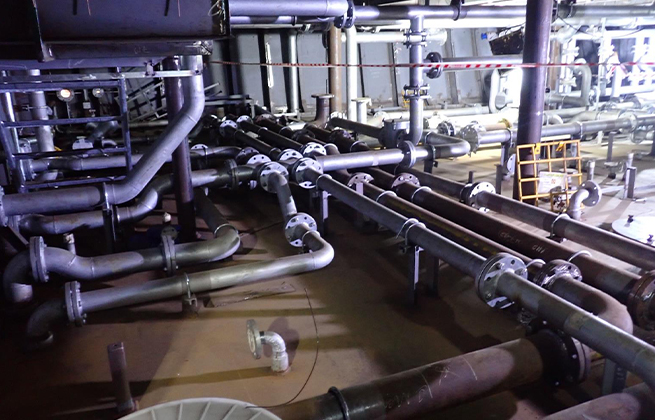

On Menawethan, Luke will attend the final inspection of the propellers and tailshafts, while advanced systems testing continues. Both the compressed air system and the sewage vacuum system are due to be presented for inspection by Owners and Class. Inspections of the anchor chain locker and pallet lift are also planned. Externally, the final topcoat of hull paintwork should be completed during his stay.