We are proud to be working with two leading Cornish companies, Armada Engineering Ltd and Wills Ridley Ltd, to supply hydraulic and steering systems for our new vessels, Scillonian IV and Menawethan.

Armada Engineering Ltd and Wills Ridley Ltd both have long histories of working with the Steamship Group, providing maintenance support on the company’s current vessels for more than 30 years.

Falmouth-based Armada is a world leader in marine hydraulics and engineering, with an office and workshop in Barcelona to service the superyacht industry.

The company has an unrivalled reputation creating state-of-the-art hydraulic systems and engineering solutions for marine vessels of all kinds, and works in markets including renewable energy, oil and gas, mining and construction.

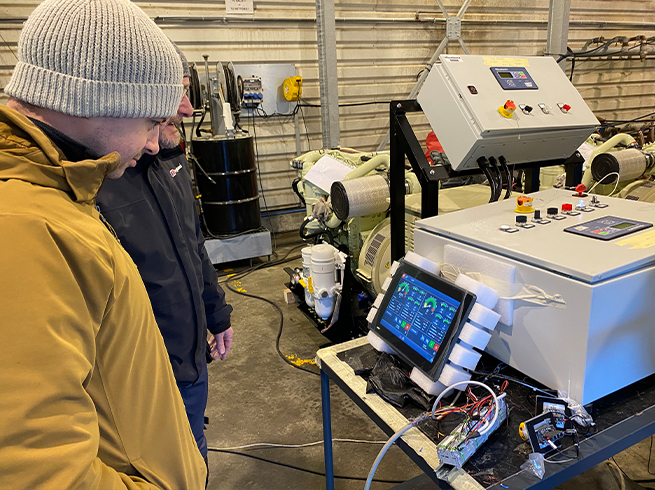

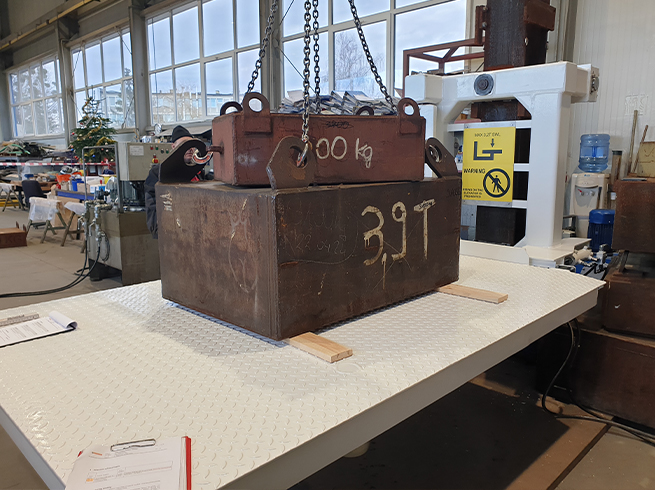

The hydraulic power units for Scillonian IV and Menawethan will be designed, built and tested at Armada’s workshop in Falmouth before being shipped to Vietnam for installation.

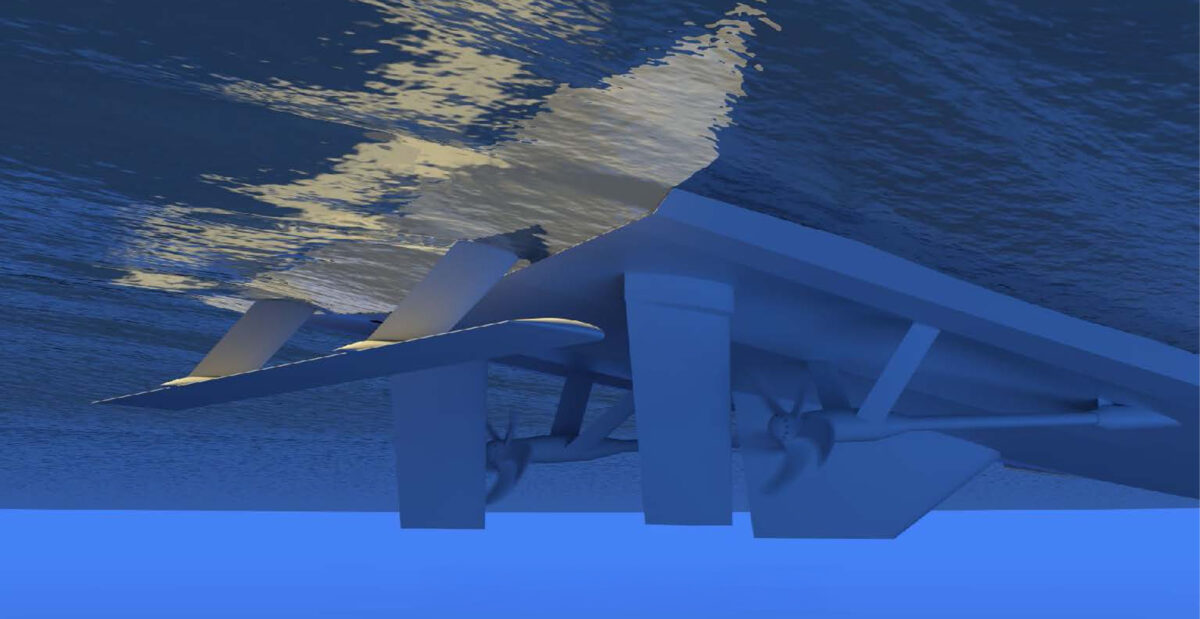

On Scillonian IV, these will power the windlass and gangway davits, and on Menawethan, the unit will power the deck hatches, cargo crane, pallet lift, side door, bow thrusters, windlass and the fore and aft capstans.

Wills Ridley has designed and manufactured hydraulic steering gear, electrical controls and rudders since 1963. With agents in 32 countries, it supplies the commercial, military, and superyacht marine sectors.

The components for the steering gears will be manufactured at Wills Ridley’s factory in Penryn before being installed and tested in Vietnam.

The electrical controls for Scillonian IV and Menawethan utilise state-of-the-art technology. There are multiple steering positions where the rudders can be controlled independently, and there is an option for the rudders to be synchronised electrically. The steering system must interface with other electrical systems, such as the autopilot.

As part of the safety system on board the two vessels, the steering gear is designed and manufactured in accordance with Lloyds Register of Shipping rules.

Stuart Reid, Chief Executive of the Isles of Scilly Steamship Group, said: “I am delighted that our trusted and valued relationships with Armada and Wills Ridley will continue, with the companies not only supplying the new hydraulic and steering systems, but providing ongoing technical support for the new vessels.”

Joff Collins, Managing Director of Armada, said: “We are genuinely honoured to be continuing our long association with the Isles of Scilly Steamship Group. We’ve been providing maintenance support to the Group’s fleet of vessels for 30 plus years, so we understand what a lifeline they are to the local community.

“I’d like to thank the Steamship Group for a successful partnership spanning three decades, and to our technical director Alan Rowe for bringing this project to fruition with the help of our in-house design team Mike Tonkin, Murray Walker and Ben Rowe.”

Ryan Kitchener, Director of Wills Ridley, said: “These vessels have been discussed for many years, and it is great to see the project come to fruition. As a proud Cornishman, it is very rare to work on new-build vessels of this size that will operate on our doorstep. Everyone at Wills Ridley is excited to be part of this project.

“I look forward to attending the sea trials and using Scillonian IV in future as a passenger with friends and family once the vessels are in service.”

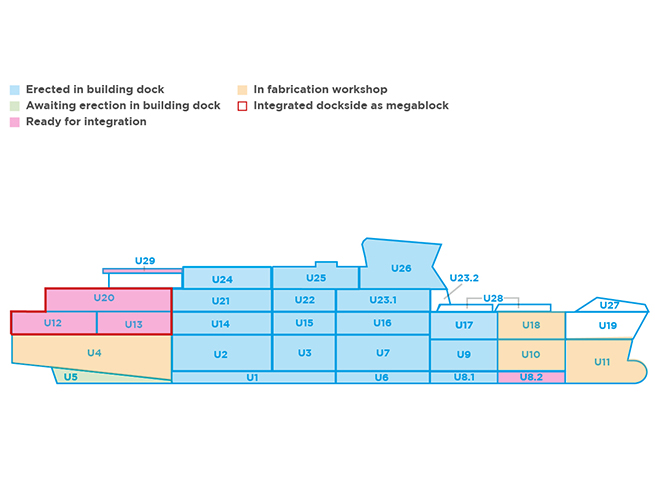

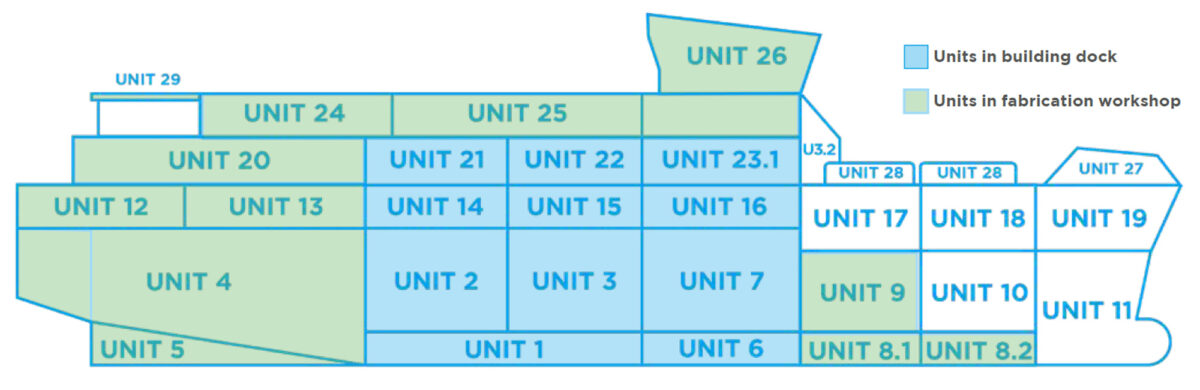

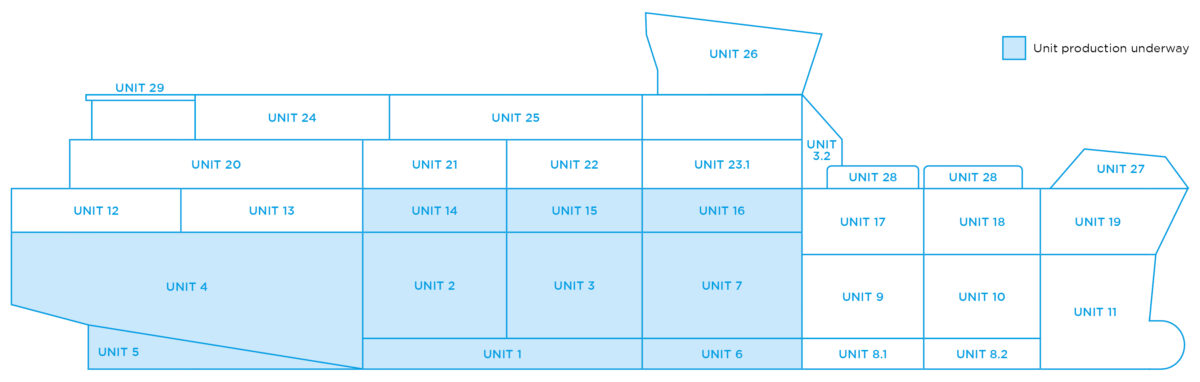

Scillonian IV and Menawethan are being built by Piriou, and are on schedule to be delivered in 2026 to meet the travel and freight requirements of the Isles of Scilly for generations to come.

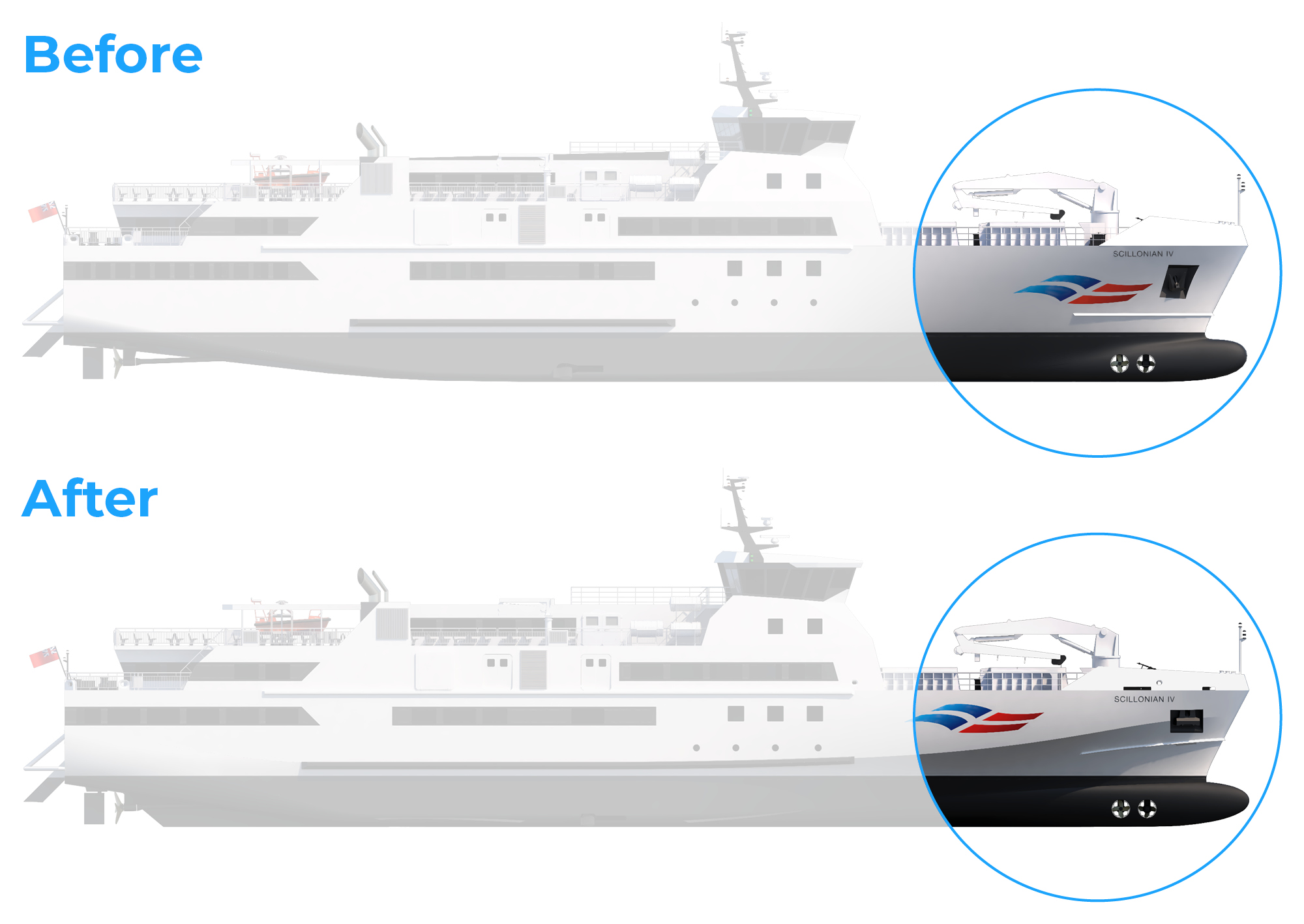

The new vessels will feature a range of new technologies, helping to improve resilience, comfort and reliability. Scillonian IV will carry up to 600 people (a 24% increase on current levels) whilst reducing journey times. It will feature roll and pitch reduction systems, to enhance passenger comfort, and is designed utilising modern propulsion technologies that improve efficiency and reduce environmental impact. The vessel is also designed to integrate further enhancements as technology develops.

Menawethan will also include a range of improvements on the current vessel, including a much-enhanced cargo capacity and an improved capacity for perishable, chilled and frozen goods, meaning that supplies can be transferred between the mainland and the islands more reliably all year round. The freight vessel will incorporate a passenger lounge with accommodation for 12 passengers.