Construction process explained

Site manager Peter Broad explains the technical side of the steel cutting progress.

Steel cutting is not only a contractual milestone but is the start of the production and fabrication of a ship.

The steel for both vessels has been delivered to Piriou shipyard in Ho Chi Minh City, Vietnam.

The steel plate and sections are approved by Lloyd’s Register, the leading provider of classification and compliance services to the marine industry. Surveyors from Lloyd’s Register have certified the steel for marine use, specifically for our project, as part of its supply chain and quality assurance measures.

The Lloyd’s Register unique certificate number is hard stamped onto each steel plate, which corresponds to a material/mill certificate. The details on the mill certificate are unique to each plate and show the grade of steel, its chemical properties and mechanical properties, including strength and ductility. These quality tests are carried out at the steel mill and witnessed by the attending Lloyd’s Register surveyor.

When the plate is received in the shipyard it goes through a blasting process carried out in a closed machine that blasts both surfaces of the plate with shot to a minimum standard of SA2.5. This not only removes any mill scale and rust, but also provides a rough finish so that a shop primer paint can be applied immediately in a semi-automatic process.

The purpose of the shop primer is to stop any further rusting and to make it easier to mark out the plate for cutting into distinct pieces for fabrication. The shop primer paint is also approved by Lloyd’s Register so it does not contaminate the welding processes.

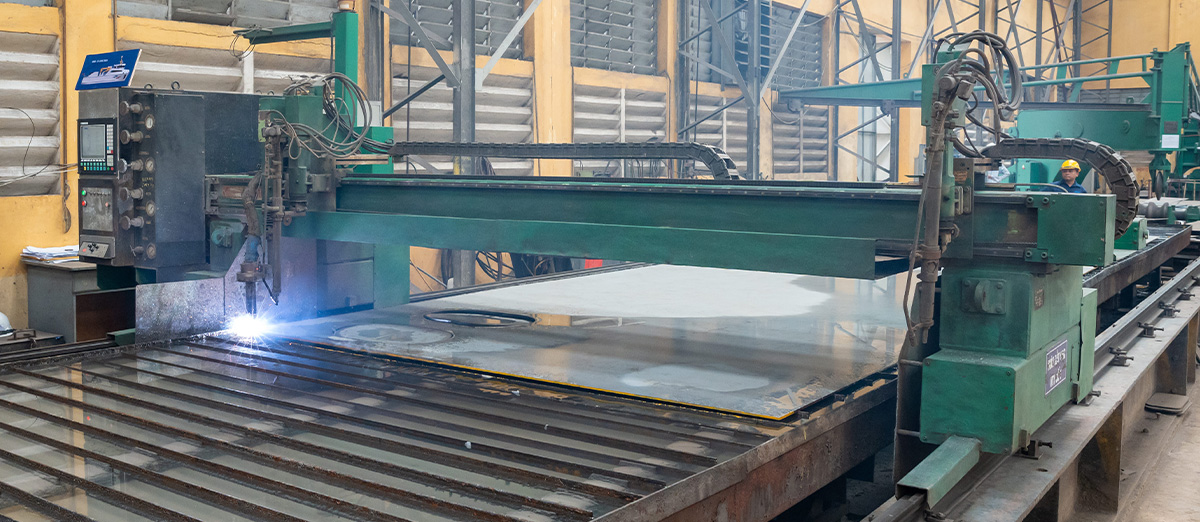

The plate is then transferred to the cutting table which is a plasma cutter that is controlled by Computer Numeric Control (CNC). This is programmed with a ‘nesting plan’ that is like a jigsaw and allows the maximum number of small component pieces to be cut out of one steel plate with minimum waste. Each part cut from the parent plate has a unique part number and is traceable back to the original plate.

Once the steel plate is cut into small component pieces it is ready to move to the panel workshop where the first parts are welded together.

Photo diary

Peter Broad has been keeping a photo diary of the new vessels’ construction in Vietnam, the below all show some of the the cargo vessel hull block construction process.

| 3RD JULY Component parts for sub-assemblies cut from LR Grade parent steel plate.  |

3RD JULY Sub-assembly components being prepared on the dockside.  |

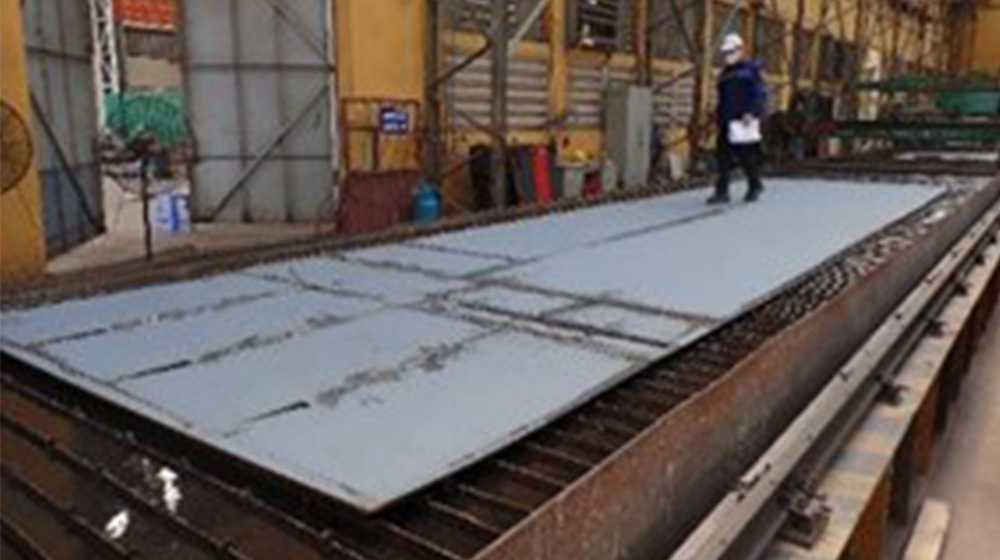

19TH JULY Hull Block U3 Tank Top prepared ready for welding.  |